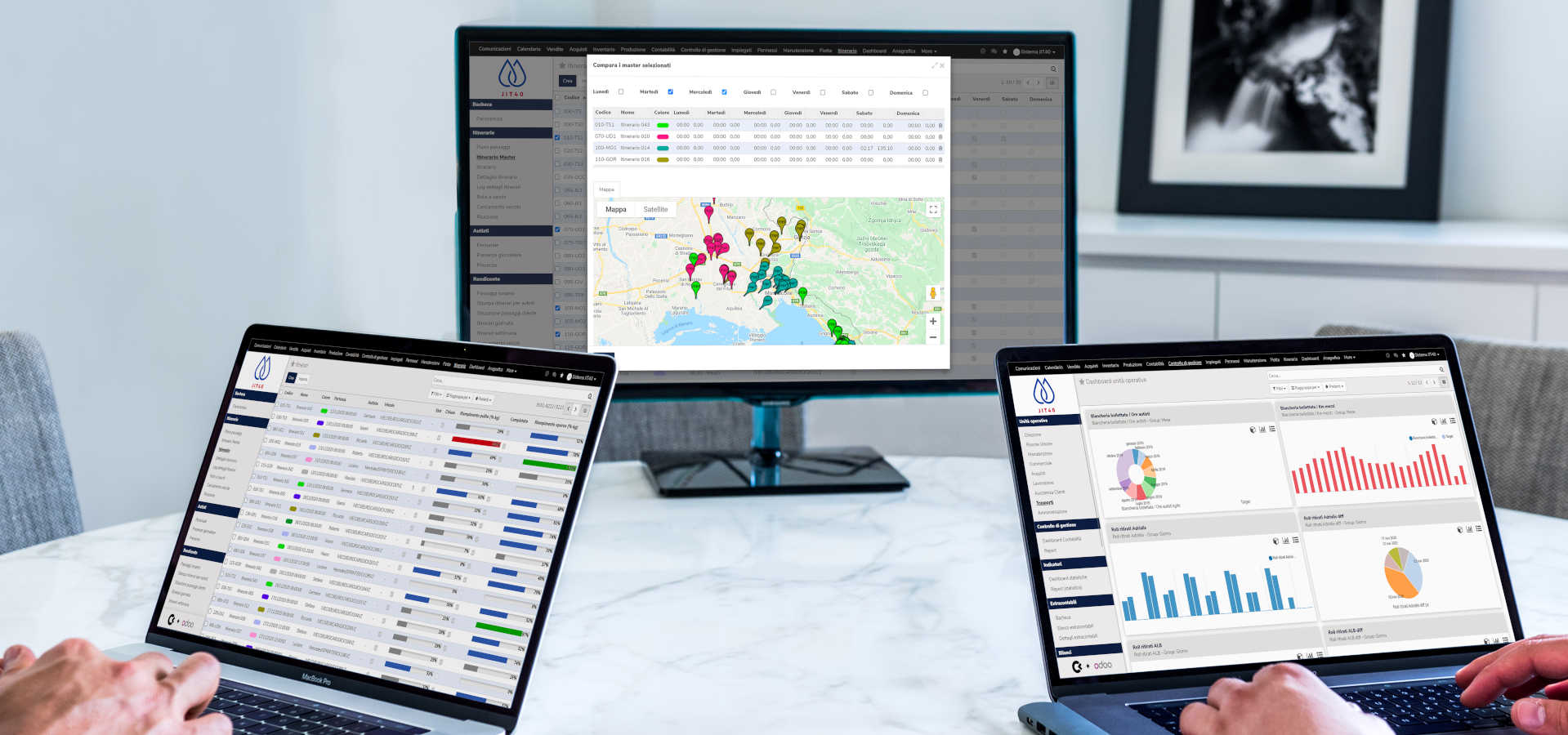

Itineraries / Drivers

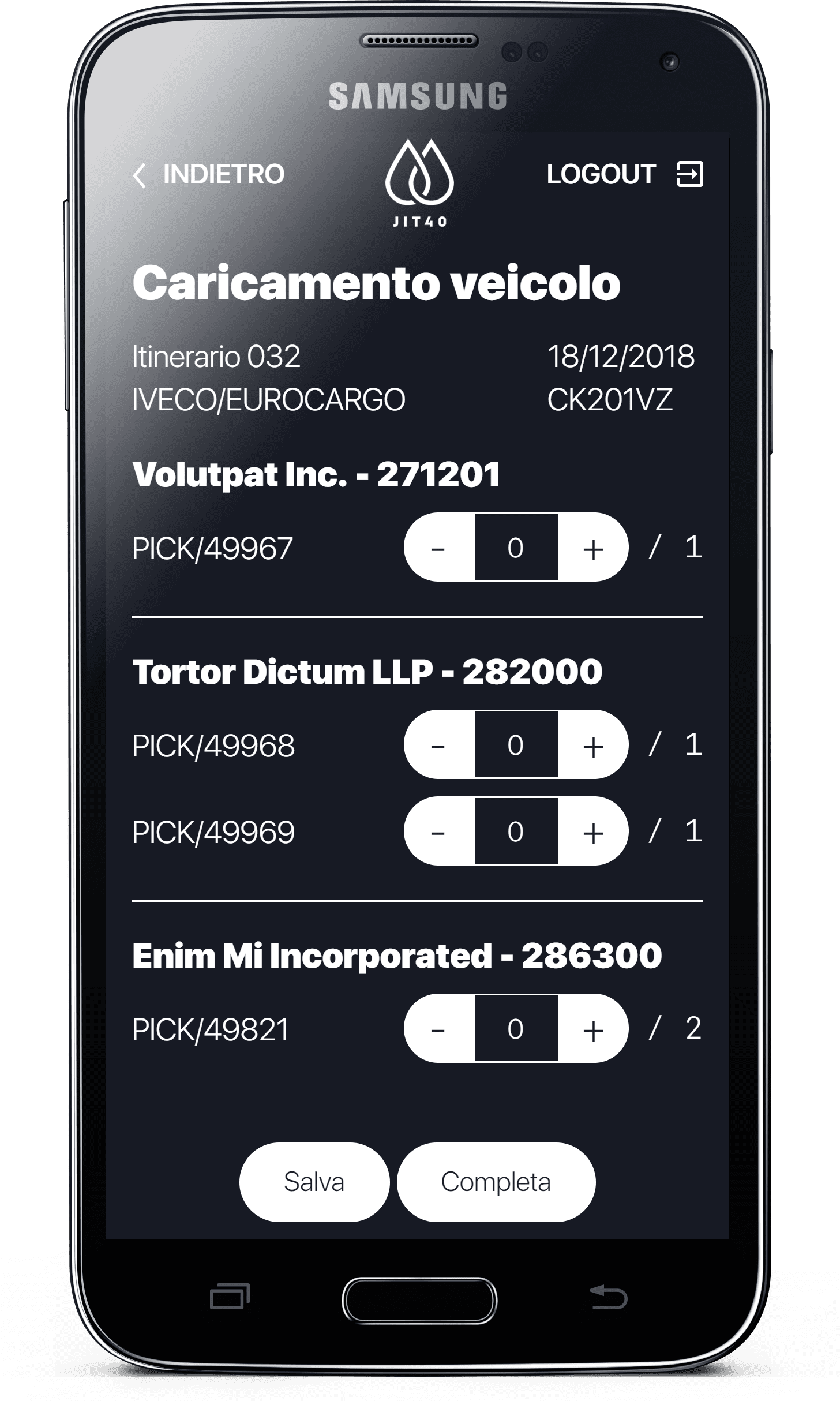

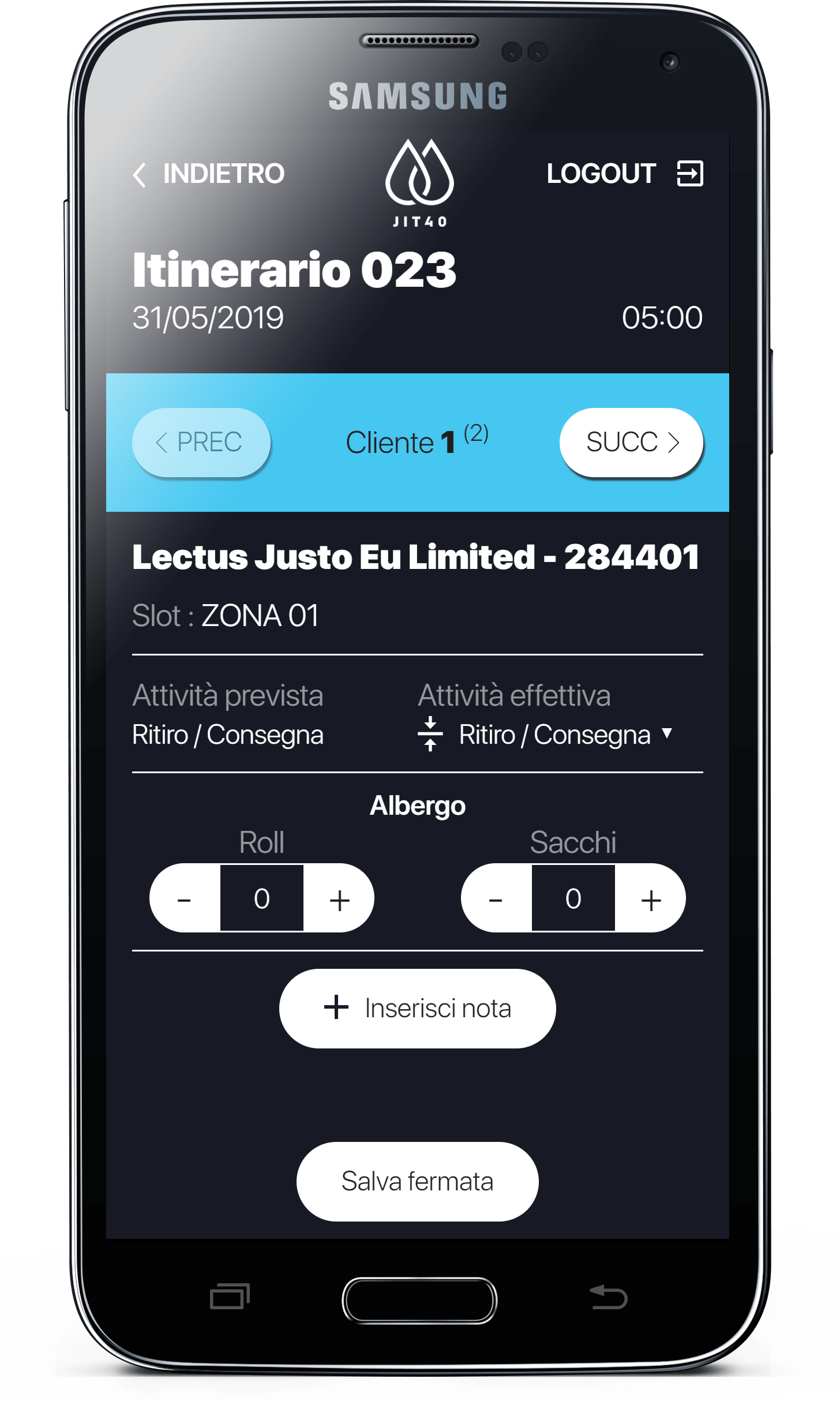

Drivers in charge of collecting and delivering items from and to customers may use a dedicated mobile app in order to share with the head office real-time updates regarding all scheduled activities that affect the production flow. This data exchange may be delayed if an active connection is unavailable.

Each driver logged into the system can access the list of daily itineraries and check related stops (address, customer, activity, and schedule). At each stop, the driver records the type of activity carried out, indicating the number of carts and bags withdrawn and/or delivered; every delivery is then validated by the customer’s signature.

Itineraries / Drivers

Counting / Counting machines

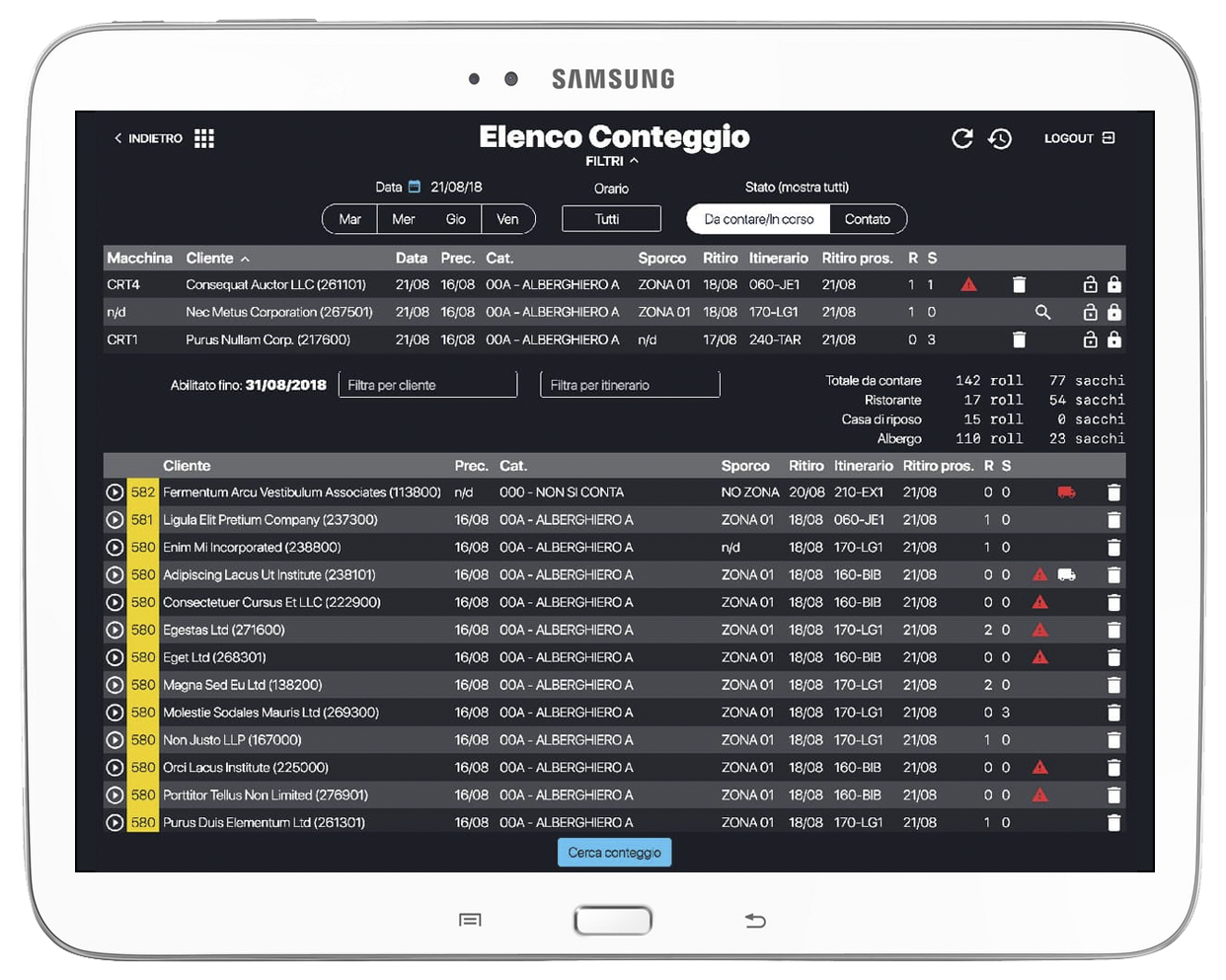

This application supports operators in charge of sorting and feeding items to the counting machines.

The interface displays information related to the counting, which can be filtered according to different parameters. For instance, the operational status can be set as follows:

• in progress (counting is ongoing)

• to be counted (counting is pending/waiting to be started)

• counted (counting has been completed)

Each record displays all related data regarding customers, linked itineraries, and carts and bags containing linen to be counted. Special icons indicate detected anomalies, such as the presence of items not included in the contract (red triangle), or if the scheduled itinerary has not been completed by the driver.

Counting / Counting machines

Ironing / Flatwork ironing machines

This module was developed for tablets positioned at workstations where operators configure items that need to be processed on the ironing lines.

The interface displays information on all ongoing ironing orders:

• stackers: for each stacker machine, data is displayed relative to item, customer, and number of pieces counted and stacked

• performance: two graphs visually indicate the operator's performance level, both relative to the batch being processed and to the overall work shift status.

• feeding: the lower part of the screen summarises data on the ironing batch, such as starting time, duration, and number of items fed to the ironing machine.

Ironing / Flatwork ironing machines

Shipping / labelling

Items coming out of the stackers are ready for the next phase, that is, to be packaged and prepared for shipping.

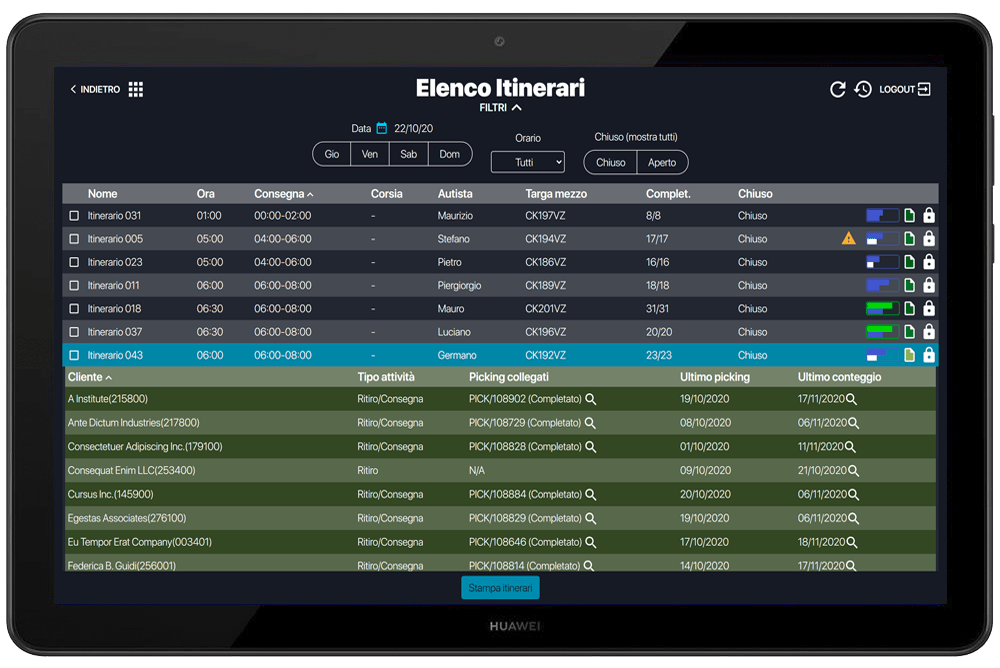

This application takes care of sorting items into packages based on their assigned customer and itinerary, as well as printing the labels. The interface displays all planned itineraries, summarising all data related to the customer and listing the type of activity (i.e. collection and/or delivery) scheduled for that specific itinerary.

Additionally, each itinerary is assigned to a specific vehicle, identified by registration plate and name of the driver. A graphic indicator visually displays info in real time regarding the space availability of the vehicle, optimising loading operations and route planning.

Shipping / labelling

Back office

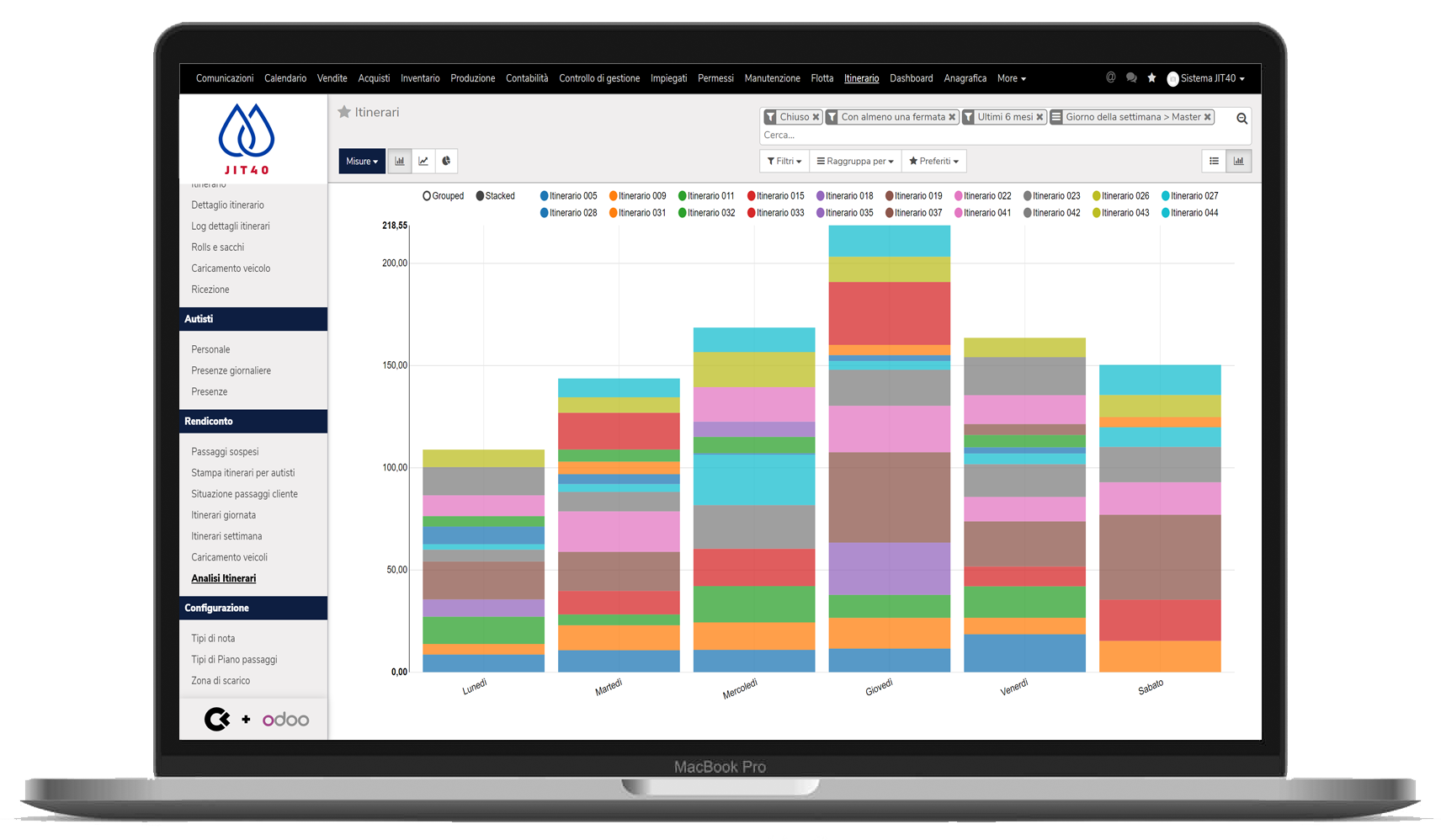

Coral JIT40 also includes a series of modules dedicated to employees working in the head office, to help them manage the CRM flow and the active and passive cycles, optimise warehouse logistics and transport planning, schedule maintenance interventions.

The specific modules for industrial accounting and management control extend the functionalities of the software, making it a 360-degree management and monitoring system, where accounting, economic and financial data as well as production data deriving from machinery converge.

These data can then be organised through customisable dashboards to obtain advanced analysis and reporting, such as: production indicators, income statement and balance sheet trends on monthly basis, cost and margin analysis of each textile product and much more.

Back office